a)Output capacity: 18000BPH~50000BPH (640ml)

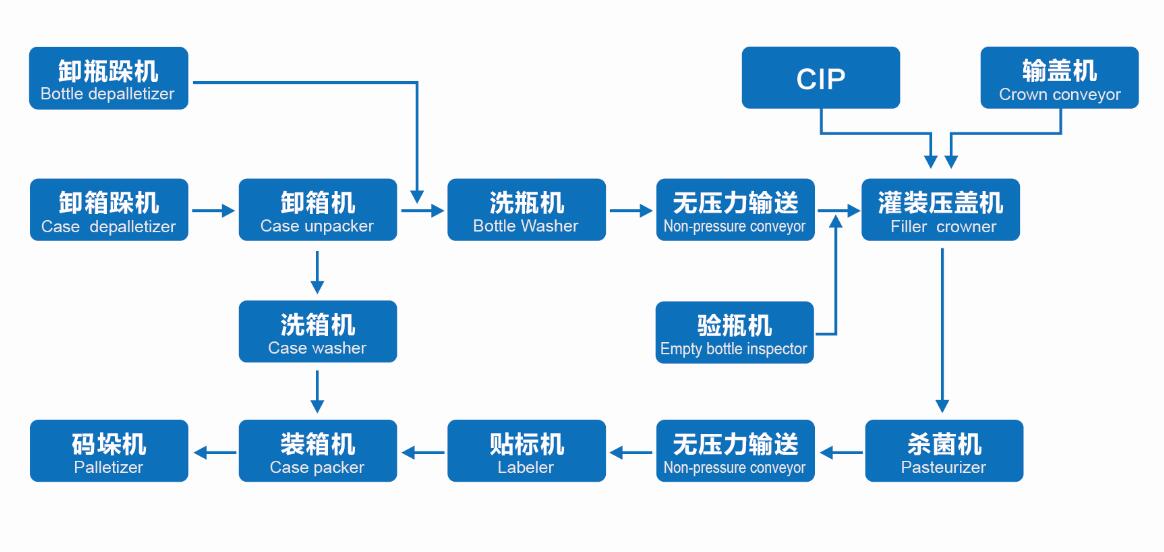

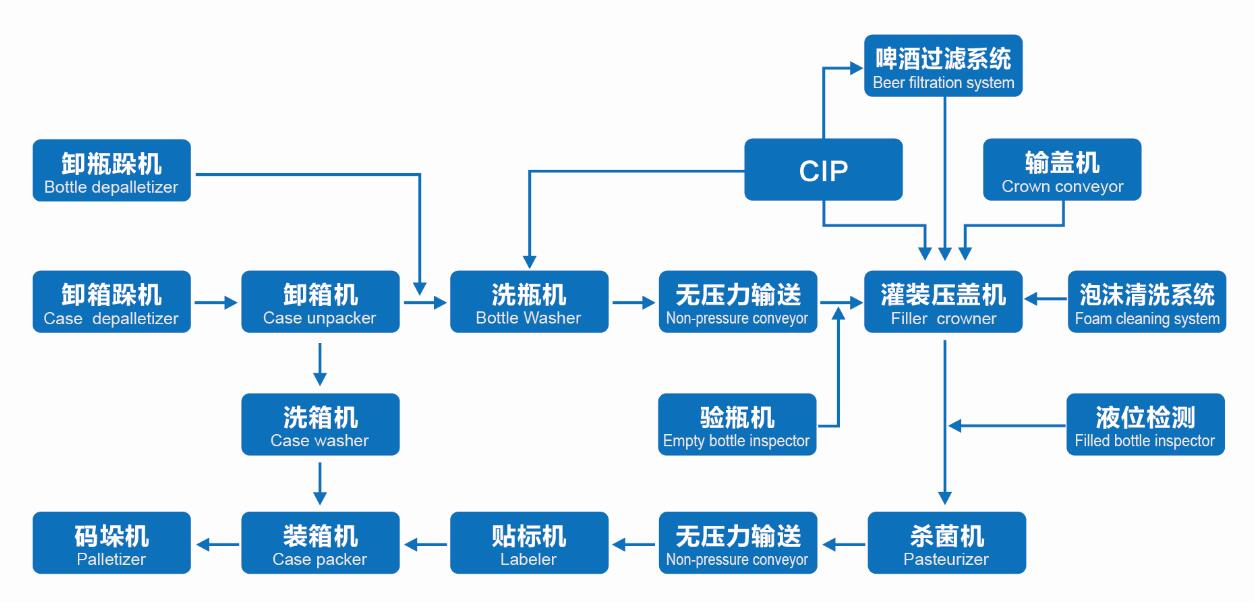

b)Main machines: depalletizer, case unpacker, bottle washer, filler, pasteurizer, case packer, palletizer, bottle & case conveyor, labeller, CIP, etc.

c)Suitable bottle: dia. ø66~80.5mm, height 210~295mm

d)Suitable cap: standard crown cap (26mm)

e)Package size: 4*6 plastic case, 3*4 carton packf)Bottling line process flow

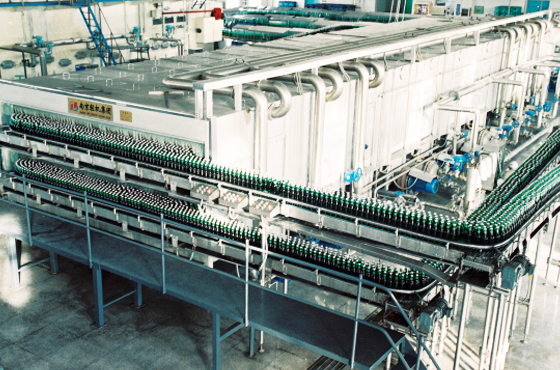

Normal beer bottling line

Draft beer bottling line

g)Technical characteristics:

1.Optimized line layout, with nominal capacity of individual machines matched according to requirements of the bottling line.

2.Full line uses pressureless transportation to achieve higher production efficiency.

3.Full line gives sufficient consideration to energy saving and emission reduction, as well as recovery of energy sources including heat and water.

4.Bottling line equipment composition can be adjusted as appropriate according to customer requirements.

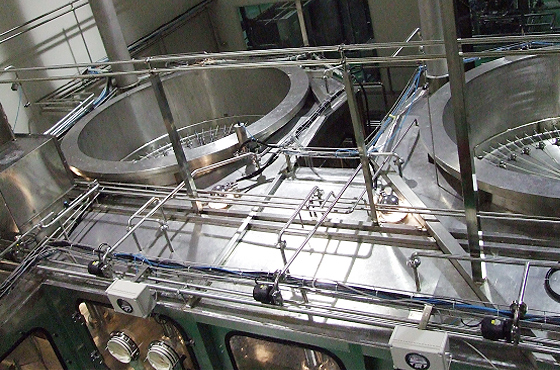

Bottling line layout

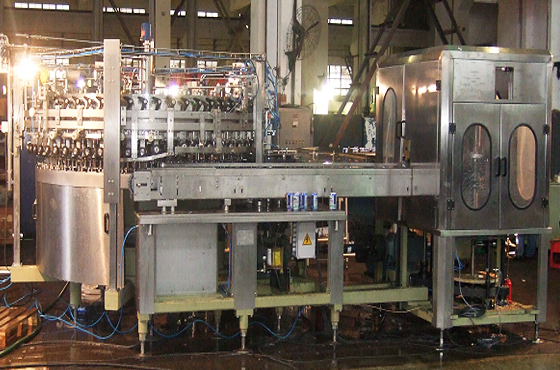

二、Beer canning line:

a)Output capacity: 12000CPH~90000CPH (330ml)

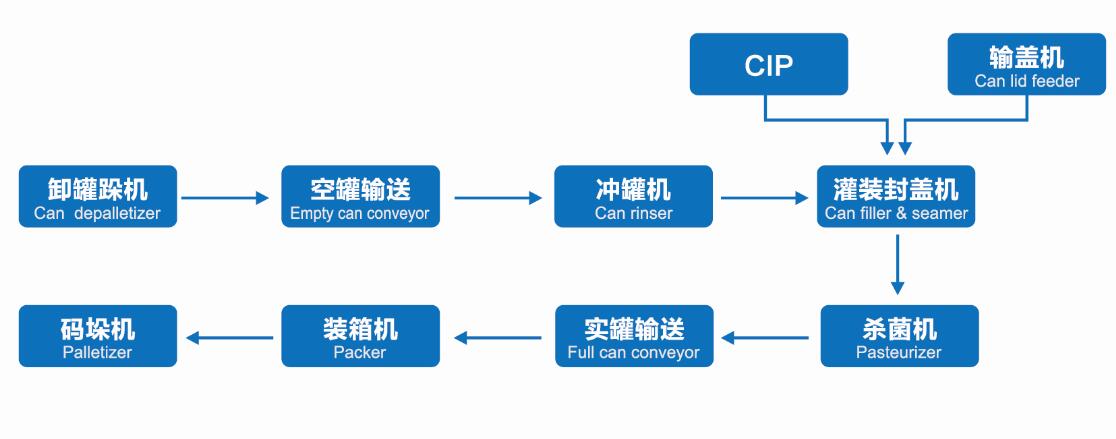

b)Main machines: depalletizer, can rinser, can filler & seamer, pasteurizer, carton packer (shrink wrapper), palletizer, can & case conveyor, CIP, etc.

c)Suitable can: 200/202/206/209 aluminum cans

d)Package size: 4*6 carton pack, 2*3/3*4 shrink wrap

e)Canning line process flow:

1.Optimized line layout, with nominal capacity of individual machines matched according to requirements of the bottling line.

2.Full line uses pressureless transportation to achieve high production efficiency.

3.Full line gives sufficient consideration to energy saving and emission reduction, as well as recovery of energy sources including heat and water.

4.Bottling line equipment composition can be adjusted as appropriate according to customer requirements.

Bottle Inverter

Bottle Inverter Can rinser

Can rinser PET bottle rinser

PET bottle rinser Glass bottle rinser

Glass bottle rinser Seamer

Seamer Pasteurizer/Cooler

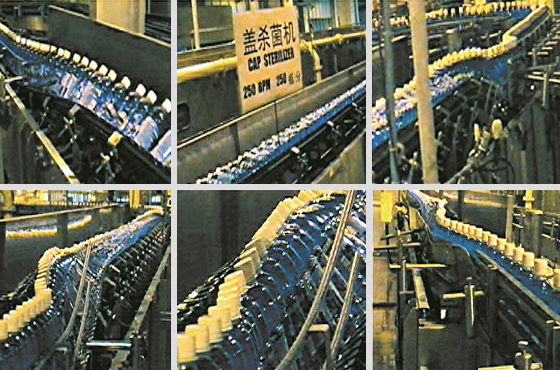

Pasteurizer/Cooler Beer Pasteurizer

Beer Pasteurizer Single-end Bottle Washer

Single-end Bottle Washer Double-end Bottle Washer

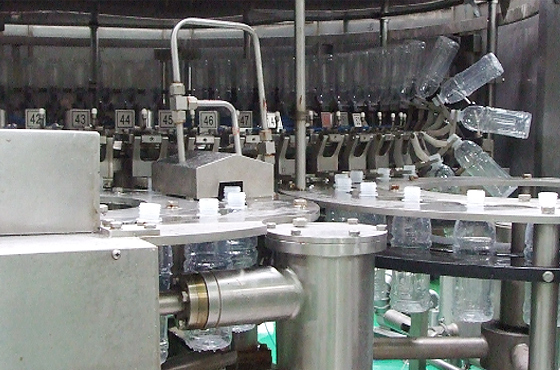

Double-end Bottle Washer Beer/CSD Can Filler & Seamer

Beer/CSD Can Filler & Seamer Tea & Juice PET Rinser/Filler/Capper Monobloc

Tea & Juice PET Rinser/Filler/Capper Monobloc Juice Rinser/Filler/Capper Monobloc

Juice Rinser/Filler/Capper Monobloc Draft Beer Rinser/Filler/Crowner

Draft Beer Rinser/Filler/Crowner Beer Filler & Crowner

Beer Filler & Crowner

Location:

Location: